Covid-19 brings opportunities and challenges

RFID laundry has been a hot during the COVID-19. Under the influence of the Covid-19 pandemic, laundry had been pushed to the list of essential service industries and was facing more opportunities and challenges than before. With the introduction of the RFID management system, handover and counting the number of laundry tasks will not be a bothering problem anymore, and the whole laundry cycle can be tracked by RFID laundry tags.

- How to reduce the time spent on the handover of laundry tasks?

- How to quickly count the number of laundry tasks?

- How to reduce the possibility of being infected with Covid-19 in the preparation for laundry?

Step1: Register Information

Each RFID laundry tag has a chip with a unique UID code. Writing the linen or garments details into the chip, like serial number, product type, the place comes from or the owner’s information, etc. Then register the chip information and corresponding linen or garments details in the laundry system.

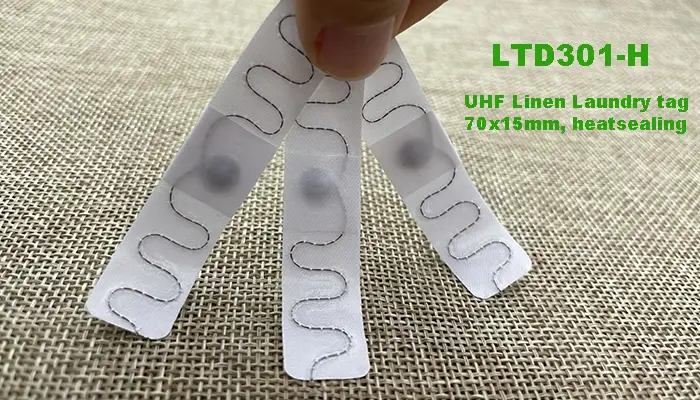

Step2: Installation of RFID Laundry Tags

Sewing or heat sealing the RFID laundry tag onto the linen or garments.

Step3, Scanning Through UHF Gate

UHF gate provides quick and accurate bulk scanning of caged linens when passing through. After the scan, check the scanned results with the task list, and confirm whether the delivered items are consistent with the actual quantity.

Obviously, it reduces operation times and labor hours for counting and sorting to almost zero, and minimizes individual handling of clean or contaminated items hygienically.

Step4: Automated Sorting by UHF Reading Tunnel

UHF reading tunnel identifies the registered RFID laundry tags and uploads the information to the laundry system. The system receives the information and associates the items with the corresponding destination warehouse or end client. Items are sorted into varying unloading buffers depending on the destination or the item type. It greatly saves manual sorting time and reduces personnel labor.

Step5: Check the result of the laundry task with RFID Reader

The RFID reader can easily scan the tags on the cleaned items and confirm whether the quantity is consistent with the laundry task. If inconsistent, items can be tracked and located through the UID number of the tags in the system.

Indispensable consumable in RFID laundry cycle

RFID laundry systems use the unique UID number of RFID laundry tags to track the laundry cycle. RFID laundry tags are usually fixed on linen or garments, and data are read and written in the sort, cleaning, drying, ironing, folding, transportation and distribution, then upload to the system. The tags must be resistant to the chemicals used in the washing process, as well as the high temperatures of washing, drying, and ironing.

The outbreak of the Covid-19 pandemic had increased the workload of the laundry industry, however, the continuous shortage of chips in recent years has also limited the supply of laundry tags.

We, Proud Tek, have established a stable chip supply chain for UCODE 8 and UCODE 9.

Currently, we are able to offer about 700,000pcs linen laundry tags monthly to the global market, and also provide silicone laundry tags and PPS laundry tags. If you need more support on RFID laundry tag, just contact Proud Tek.